The 10-Minute Rule for Motorcycle Parts New Zealand Specialists

Table of ContentsThe Best Guide To Motorcycle Parts New Zealand SpecialistsThe 3-Minute Rule for Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists for DummiesAn Unbiased View of Motorcycle Parts New Zealand SpecialistsThe Best Guide To Motorcycle Parts New Zealand SpecialistsSome Known Questions About Motorcycle Parts New Zealand Specialists.Fascination About Motorcycle Parts New Zealand SpecialistsA Biased View of Motorcycle Parts New Zealand Specialists

Reach out to one of our specialists today.CNC machining innovation is promptly ending up being the centerpiece of several manufacturing procedures around the globe as a straight outcome of its lots of advantages over other methods. Furthermore, the markets that make bikes have obtained on board with this fad. The most ingenious business are currently developing their engine parts and wheels making use of machining methods initially developed for motorcycle parts.

On the other hand, the effects of sector are the main focus of this article. Allow's obtain directly into it. You may be asking yourself why we use. It is not hard to fathom the factors that caused this outcome. Currently that we have your focus allow us discuss the reasoning behind this modern-day development in the motorbike production sector.

8 Simple Techniques For Motorcycle Parts New Zealand Specialists

In enhancement, you have complete control over the look of the components, also down to the min details. Occasionally, motorcyclists might decide to spruce up their adventure by setting up aftermarket components or changing the bike's transformation.

Fascination About Motorcycle Parts New Zealand Specialists

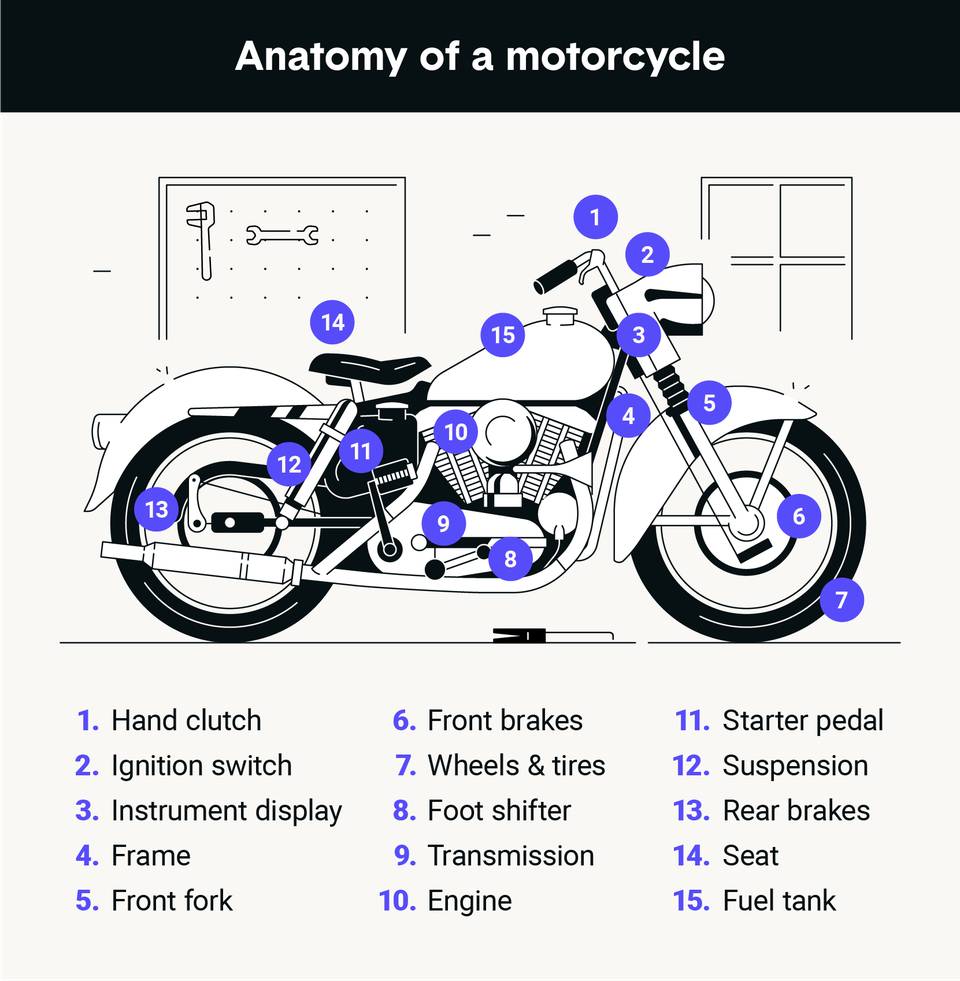

CNC machining may be utilized to make mostly all of a motorcycle's metal and plastic elements. To continue, we'll review several machined parts for motorbikes. In contrast to those on vehicles, wheels on motorbikes have a tendency to be a lot more noticeable. As an outcome, the bike's appearances might be improved with the suitable personalization of these wheels.

When personalizing the wheels, the disks are where the focus ought to be. The majority of them are made out of aluminum. Light weight aluminum alloys are popular for the superior machining capacities that they have. Milling procedures are utilized to obtain the desired level of wheel modification. An additional facet of the motorbike that may be personalized is the tires.

Everything about Motorcycle Parts New Zealand Specialists

When it comes to a lorry (or a motorbike), one of the most crucial component is the engine. A number of individuals mention it as the "heart" of the auto. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be detailed and require designs with a high level of accuracy.

Use only high-grade products, nonetheless, given that these lights are essential for the security of motorcyclists and various other vehicle drivers or people on the road, particularly at evening. Bike fronts lights have three main parts: the bulb, or light source, the lens, and the housing.

Milling processes with a remarkable coating would certainly cause the lenses having a reflective quality that is similar to that of a mirror. The cover, on the other hand, is not composed of vulnerable products; instead, it is created out of difficult polymers that can be machined right into even more detailed patterns.

Motorcycle Parts New Zealand Specialists - Questions

They commonly have intricate geometries with a wealth of min details. Motorcycle manufacturers usually cast these parts, however only for the manufacturing of bespoke parts. CNC machining is the technique of choice when producing unique pieces. Machining on 5 axes in today's globe is the methods through which any layout shape might be realized.

Pick Runsom for your customized motorbike parts! We have the capability to produce difficult and trendy parts making your motorcycle unparalleled.

Below are a few instances of metals usually used in motorbike part machining. Aluminum is the main product used by business specializing in generating custom motorbike parts to develop most of these components. In the past, we would certainly construct our engines out of cast iron. On the other hand, aluminum is rapidly ending up being the product of option, partially as a result of the reality that it is extra light-weight.

Zinc refers to another steel that is really light in weight and has wonderful machining qualities as a result of its high mechanical toughness. This product might be developed into almost any form and maintains its measurements well. Also mission-critical elements that need a high level of precision might gain from their use.

5 Easy Facts About Motorcycle Parts New Zealand Specialists Described

One more steel that sees heavy usage in the manufacturing of CNC-customized components is magnesium. It is amongst the lightest steels that are now obtainable and has excellent machinability features and stamina commensurate with its internet reduced weight. Among the disadvantages of magnesium is that its dust might quickly catch fire.

Because of its remarkable machinability and weldability, stainless steel is an alloy that is especially fit for CNC processes. Along with this, they have wonderful rust resistance and a high aesthetic appeal. Their most usual usage in generating various motorcycle components is fasteners, such as screws and bolts. Their low vulnerability to oxidation and rust makes them suitable for this usage.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

It appears that CNC turning and crushing are the fundamental processes. However, different methods exist, such as drilling. Let's examine much of these machining strategies in deepness. The CNC turning strategy is considered a subtractive production technique. Additionally, it calls for maintaining bars of material, frequently plastic or steel, ready and then turning a cutting device to remove sections of the product as the material is turned.

These methods are equally crucial and produce parts with high accuracy and consistent quality. They are specifically: grinding, laser cutting, and boring. The term "surface area finish" refers to post-processes after the first machining phase. Motorcycle Parts New Zealand Specialists. The processes help improve the total quality of the machined motorcycle elements. Below are the short intro, advantages and disadvantages of link 5 surface treatment techniques.

Some Of Motorcycle Parts New Zealand Specialists

Comments on “3 Simple Techniques For Motorcycle Parts New Zealand Specialists”